-

مكونات سيراميك الألومينا

-

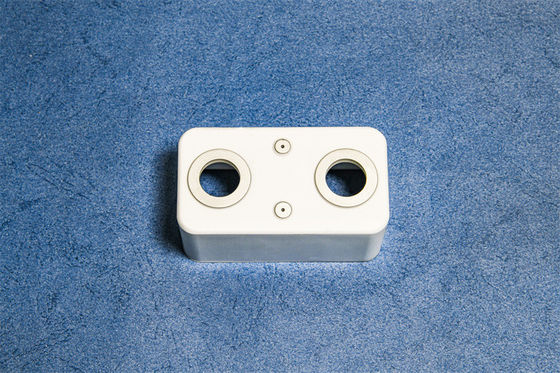

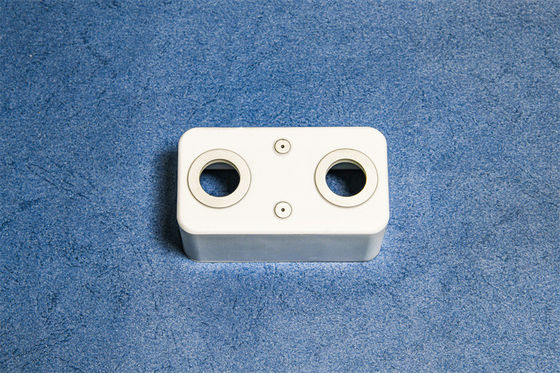

إسكان سيراميك

-

سيراميك الألومينا الممعدن

-

قطع سيراميك مخصصة

-

عازل سيراميك الألومينا

-

حلقات سيراميك الألومينا

-

سيراميك مستشعر الضغط

-

سيراميك تقني متقدم

-

سيراميك هندسي متقدم

-

فيوز سيراميك

-

كتل موصل السيراميك

-

مكونات السيراميك الإلكترونية

-

مغنطرون سيراميك

-

قطع سيراميك زركونيا

-

قضبان سيراميك الألومينا

-

السيد فارنرد سريع جدا وسهل الكلام!

السيد فارنرد سريع جدا وسهل الكلام! -

السيد جاكسونخدمة جيدة ولطيف الحديث.

السيد جاكسونخدمة جيدة ولطيف الحديث.

High Dielectric Constant Alumina Ceramic Components for Extreme Environments and Temperature Applications

اتصل بي للحصول على عينات مجانية وكوبونات.

ال WhatsApp:0086 18588475571

ويتشات: 0086 18588475571

سكايب: sales10@aixton.com

إذا كان لديك أي قلق ، فنحن نقدم مساعدة عبر الإنترنت على مدار 24 ساعة.

x| Dielectricity Constant | 9-9.7 / 1MHz.25℃ | Breakdown Voltage | 20 KV/mm |

|---|---|---|---|

| Bulk Density | 3.6g/cm3-3.9g/cm3 | Surface Finish | Polished |

| Thermal Expansion Coefficient | 8.2 X 10^-6 /K | Hardness | 9 On Mohs Scale |

| Flexural Strength | 200-400 MPa | Usage | Ceramic Chamber DC Contactor Assembly |

| إبراز | High Dielectric Constant Alumina Ceramic Components,Extreme Environments Alumina Ceramic Parts,Temperature Applications Al2O3 Ceramic Components,Extreme Environments Alumina Ceramic Parts,Temperature Applications Al2O3 Ceramic Components |

||

Product Description:

Alumina Ceramic Components are essential elements in various industrial applications due to their exceptional properties. These components are crafted from high-quality materials to ensure durability and reliability in challenging environments. The Alumina Ceramic Slice, Alumina Ceramic Plate, and Alumina Ceramic Case are specifically designed to meet the stringent requirements of the ceramic chamber DC contactor assembly.

One of the key features of these Alumina Ceramic Components is their impressive Dielectric Constant, ranging from 9 to 9.7 at 1MHz and 25℃. This attribute makes them ideal for applications where electrical insulation and signal transmission are critical. Additionally, the components exhibit a RoHS Hardness equal to or greater than 85, ensuring resistance to wear and tear over prolonged usage.

Moreover, the Alumina Ceramic Components boast a Thermal Expansion Coefficient of 8.2 x 10^-6 /K, which contributes to their stability under fluctuating temperatures. This characteristic prevents cracking or warping, thereby enhancing the longevity of the components. The Bulk Density of these components falls within the range of 3.6g/cm3 to 3.9g/cm3, signifying their robust construction and ability to withstand mechanical stresses.

Designed for the specific application of Ceramic Chamber DC Contactor Assembly, these Alumina Ceramic Components offer superior performance and reliability. Whether used as Alumina Ceramic Slices for precise positioning, Alumina Ceramic Plates for structural support, or Alumina Ceramic Cases for housing delicate components, these components excel in their respective roles.

In conclusion, the Alumina Ceramic Components represent a pinnacle of engineering excellence, combining high Dielectric Constant, RoHS Hardness, Thermal Expansion Coefficient, and Bulk Density to deliver unmatched performance in demanding environments. Their tailored design for the Ceramic Chamber DC Contactor Assembly ensures seamless integration and optimal functionality, making them a preferred choice for industries requiring precision and durability.

Features:

- Product Name: Alumina Ceramic Components

- Usage: Ceramic Chamber DC Contactor Assembly

- Package: Carton

- Dielectricity Constant: 9-9.7 / 1MHz.25℃

- Form: Solid

- Maximum Use Temperature: 1600-1650℃

- Keywords: Alumina Ceramic Pad, Alumina Ceramic Plate, Alumina Ceramic Ring

Technical Parameters:

| Technical Parameter | Value |

|---|---|

| Breakdown Voltage | 20 KV/mm |

| Form | Solid |

| Gas Tightness | ≤1.0*10^-11 |

| Flexural Strength | 200-400 MPa |

| Dielectric Constant | 9-9.7 / 1MHz.25℃ |

| Package | Carton |

| Surface Finish | Polished |

| Thermal Conductivity | 25 W/mK |

| Dielectric Constant | 9.6 |

| Thermal Expansion Coefficient | 8.2 X 10^-6 /K |

Applications:

The Antaeus Alumina Ceramic Components are versatile and durable products that find applications in a wide range of industries and scenarios. The high-quality alumina ceramic material used in these components ensures excellent performance and reliability in demanding environments.

Product Application Occasions and Scenarios:

- Alumina Ceramic Shell: The Antaeus alumina ceramic shell is ideal for use in electronic enclosures, sensor housings, and protective covers due to its high dielectric constant of 9.6 and excellent thermal conductivity of 25 W/mK. These properties make it suitable for applications requiring efficient heat dissipation and electrical insulation.

- Alumina Ceramic Case: The Antaeus alumina ceramic case is perfect for housing delicate electronic components, power modules, and high-frequency devices. With a dielectricity constant of 9-9.7 at 1MHz and 25°C, it provides reliable insulation and protection against electromagnetic interference.

- Alumina Ceramic Pad: The Antaeus alumina ceramic pad is widely used in semiconductor manufacturing, power electronics, and automotive engineering. Its high bulk density of 3.6g/cm3-3.9g/cm3 and low thermal expansion coefficient of 8.2 x 10^-6 /K make it suitable for applications requiring precise thermal management and dimensional stability.

Originating from Hunan, China, these Alumina Ceramic Components can be customized to meet specific requirements, with a negotiable minimum order quantity and pricing. The components are carefully packaged in inner vacuum packaging and outer cartons to ensure safe delivery within 15-45 days. Payment terms can be arranged via T/T or negotiation, and the supply ability is guaranteed to meet the demands of any project.